Home of virtual commissioning since 1995

Virtual commissioning of machines and systems in real time

Planning, testing and optimising efficient and safe systems

with the help of WinMOD real-time simulations

The WinMOD concept

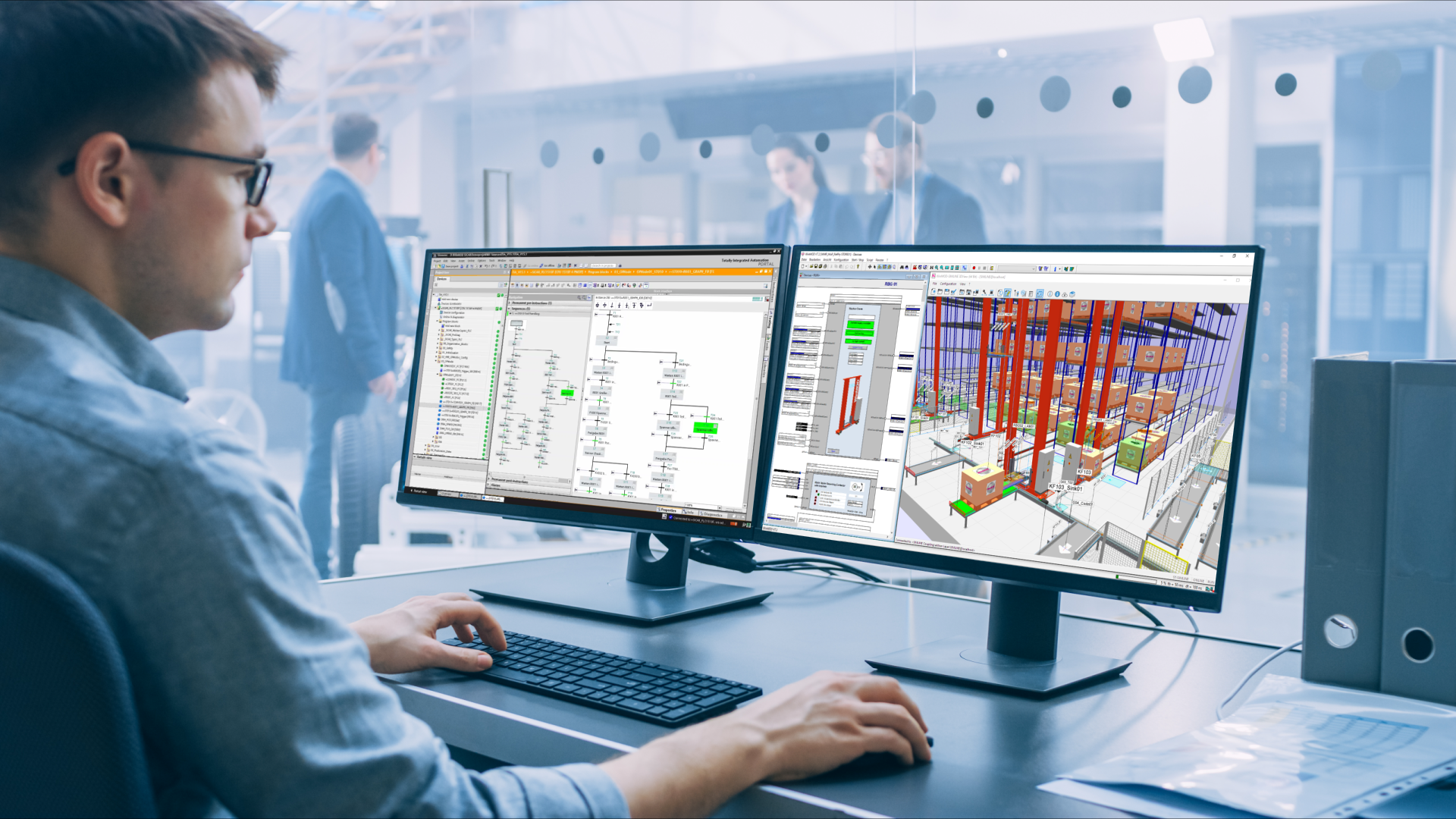

WinMOD is the leading modular real-time simulation platform for virtual planning, commissioning, validation and optimisation of automation projects. With WinMOD, you can create functional digital twins for commissioning your machines and systems under realistic conditions - simply, quickly and safely in the office. The platform seamlessly links your automation systems to the behavioural model and, thanks to the option of process, 3D and various co-simulations, offers comprehensive tools for the holistic representation and testing of complex automation solutions.

WinMOD allows you to plan, test, validate and optimise your automation projects under realistic conditions.

Our powerful simulation platform virtually reproduces real machines and systems - true to detail, dynamically and in real time.

From drive and sensor technology (electrical, pneumatic, hydraulic) to complex production and process systems, everything can be simulated.

Our outstanding system couplings to automation systems (AS) such as PLC, IPC, DCS (referred to as WinMOD configurations) enable a seamless connection in real time - without modification to the AS project.

They are therefore an essential basis for the use of simulations in the automation environment.

Numerous co-simulations extend the WinMOD system platform with integrated interfaces to leading robot manufacturers, process simulators and digital planning tools in real time. WinMOD offers an optimised runtime environment for the integration of standardised simulation solutions such as FMUs (FMI standard).

WinMOD enables real-time 3D simulation with the SIMLINE extension. Here you can directly import your CAD data in many different formats. SIMLINE 3D material flow simulation offers library-based solutions and workflows for all your technologies, from logistics and mechanical engineering to robot-integrated systems.

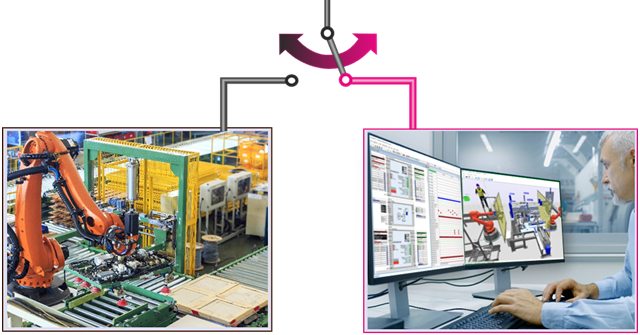

Virtual commissioning (VIBN)

Virtual commissioning (VIBN) with WinMOD allows automation software and automation structures to be tested quickly and reliably, intensively and risk-free before the actual installation. This saves time and costs, as possible planning errors and implementation errors in programming are recognised and rectified at an early stage.

WinMOD supports both real automation systems (Hardware in the Loop = HIL) and virtual ones (Software in the Loop = SIL).

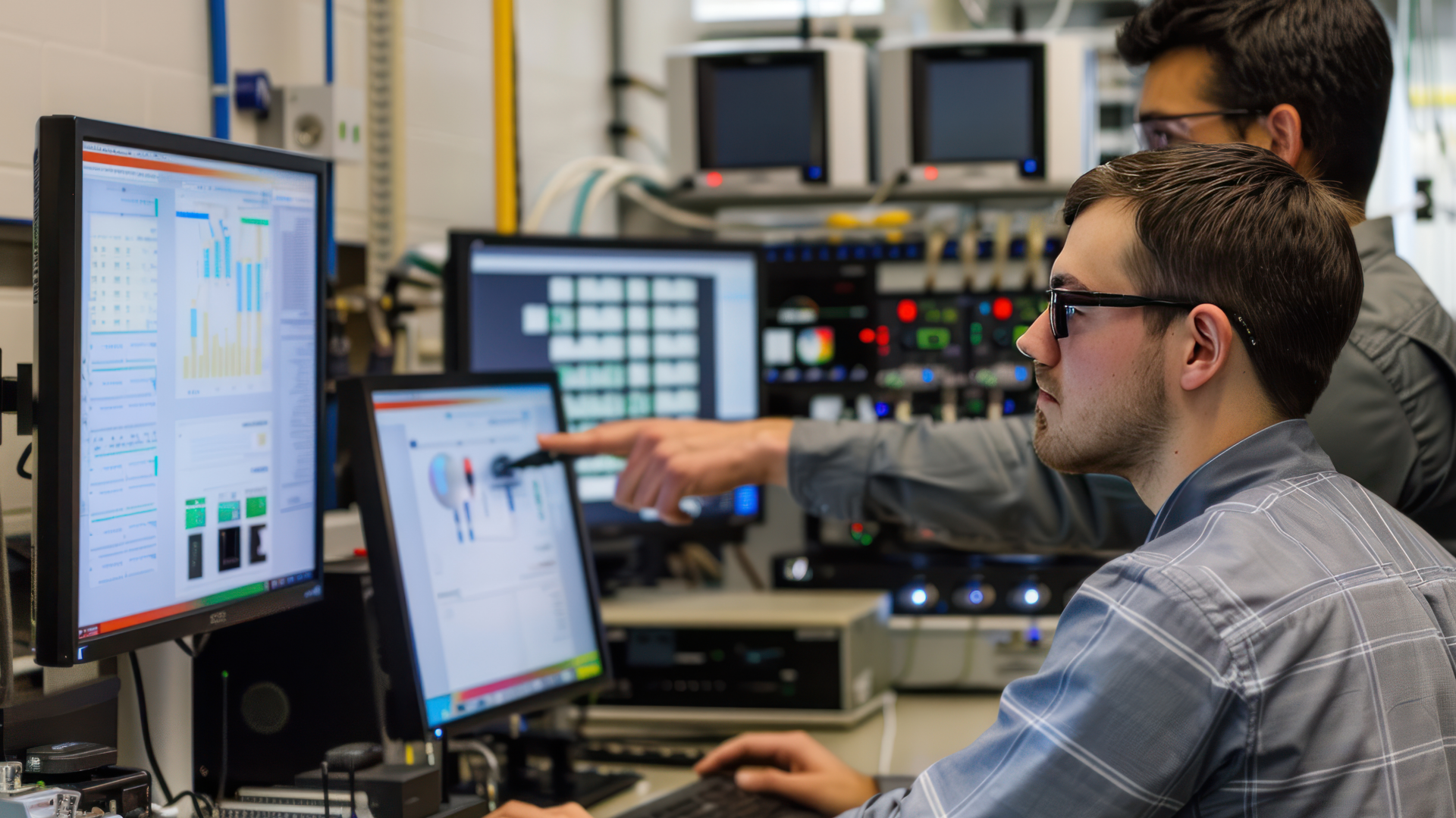

Factory Acceptance Test (FAT)

Factory acceptance tests (FAT) are a tried and tested part of the software testing process for automation systems in areas characterised by process engineering, such as chemicals, pharmaceuticals, building materials, water or waste water. Previously carried out with a high level of hardware input - such as physical switches and potentiometers - the test has been carried out as virtual commissioning since 1995 thanks to WinMOD. All levels of automation are tested: from PLC to HMI to the operational management level (MES) - efficiently, digitally and realistically.

Operator training with the digital twin

A successfully completed VIBN or FAT with WinMOD creates the basis for a practical Operator Training System (OTS). The resulting digital twin faithfully reproduces your automated system - including the original software version of all automation systems involved. Operators and maintenance personnel train typical procedures, emergency scenarios and complex processes in a safe and realistic environment - without affecting real production. The behaviour of the system can be experienced under varying conditions, training courses can be repeated flexibly and adapted precisely to different requirements.

Software test

WinMOD creates test environments for developers and engineers to test their AS software under realistic conditions and variable load scenarios - without any risk. Thanks to the detailed simulation of the entire machine/system, errors can be recognised and rectified at an early stage - even before they are actually installed.

Various manipulation options - manual, automated and imported via external software test tools - allow test scenarios that are not risk-free in a real environment, but are necessary.

This creates extreme security for programmers, commissioning engineers and all downstream trades involved in the processes.

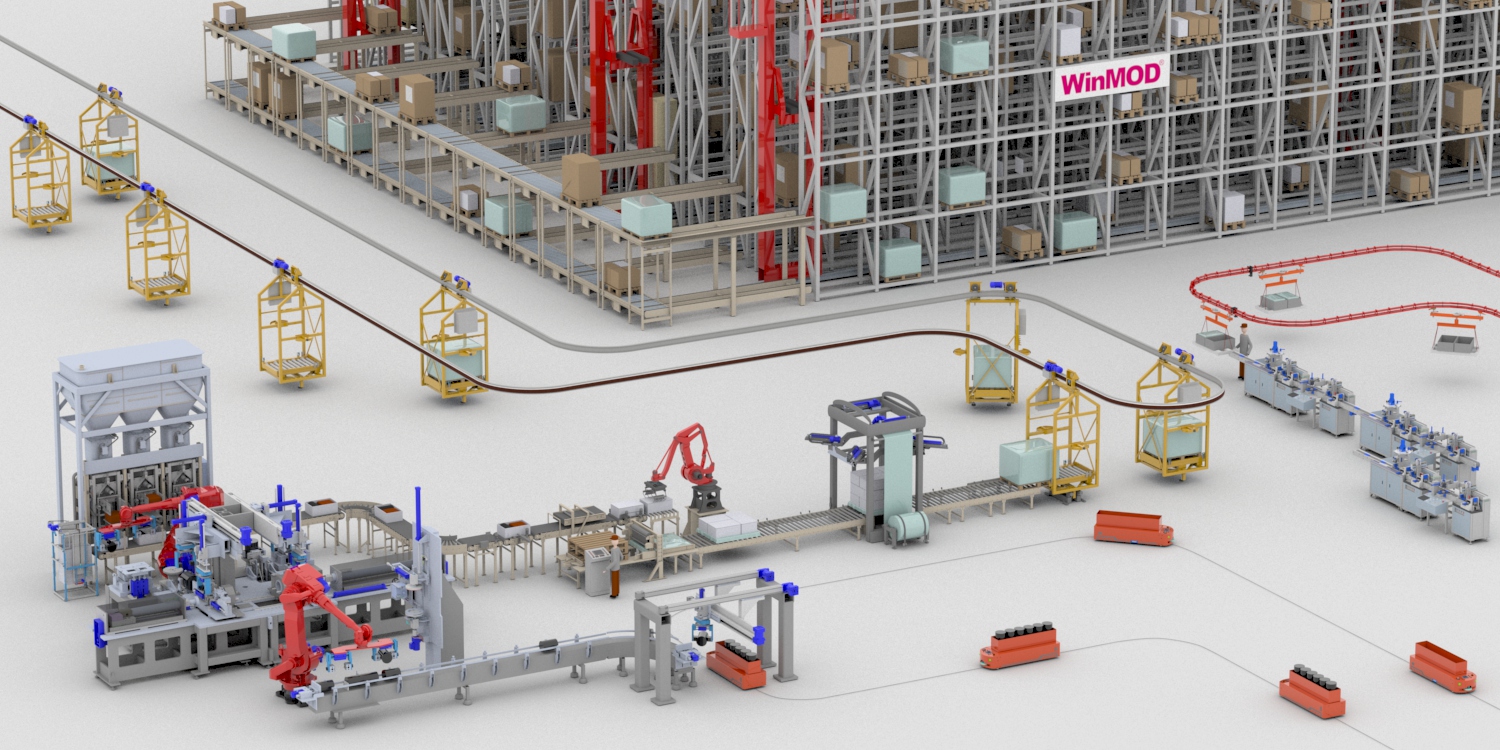

Factory automation with WinMOD

Whether production lines with robots or complex, fully automated warehouses: WinMOD realistically depicts your production and transport technology. Actuator and sensor systems such as frequency converters, RFID and other identification systems are virtualised. Material flow systems (MFS) in particular are coupled for strategy tests.

- Container conveyor technology

- Pallet conveyor technology

- Automated storage systems

- Mechanical engineering

- Robotics

- Pick-and-place systems

- Electric overhead and floor conveyors

- Power-and-Free

- Driverless transport systems

- Production lines

Process automation with WinMOD

WinMOD is the right system for simulating processes with liquids, gases and bulk solids. With highly efficient libraries, you can virtualise controlled systems, chemical reactors, temperature curves, hydraulic and pneumatic systems in all variants in real time. Link small and large control systems through to complete process control systems.

- Chemistry/Pharmacy

- Biotechnology

- Food

- Coal and steel industry

- Air conditioning/refrigeration technology

- Energy

- Water/waste water

- Transport and infrastructure

- Building automation

- Shipbuilding/offshore plants

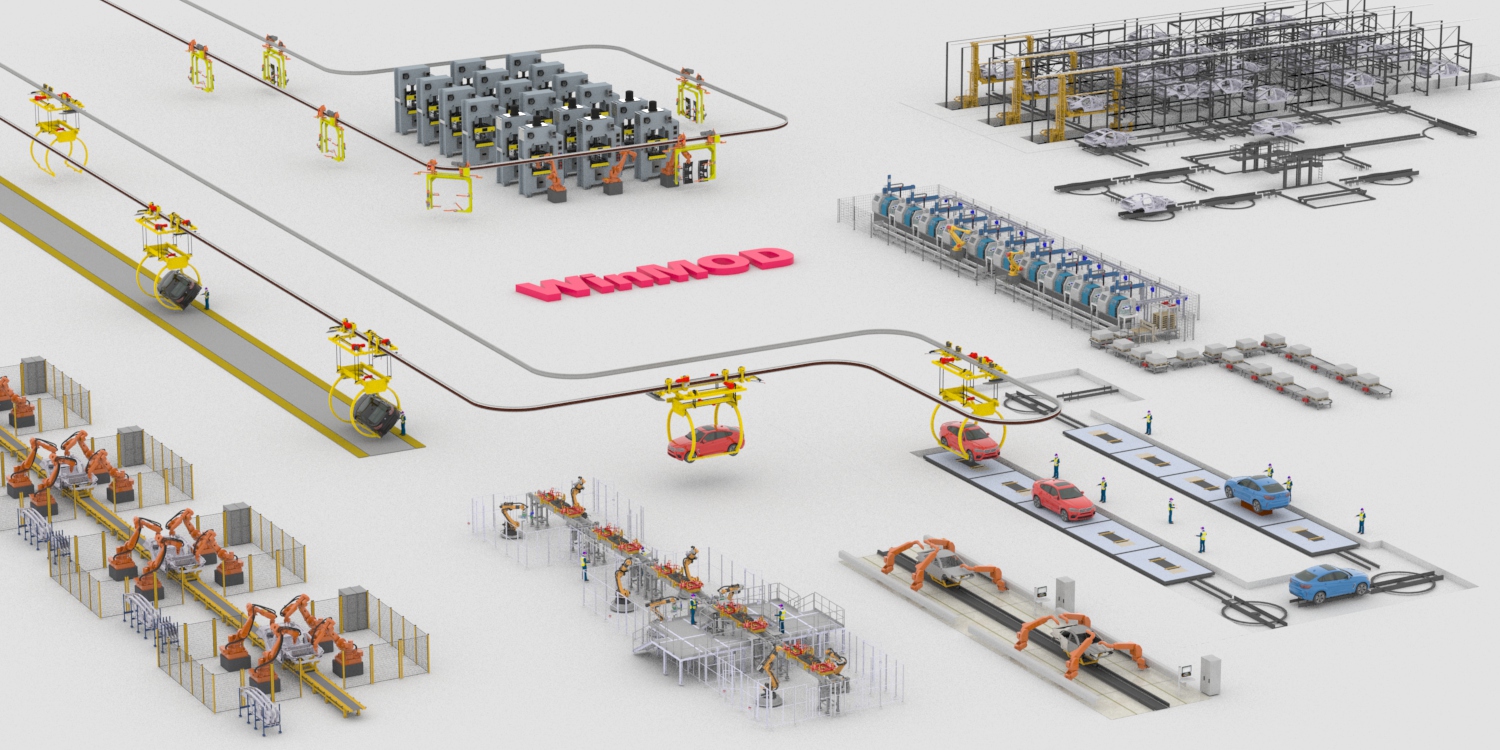

Automotive engineering with WinMOD

WinMOD is used to build „real“ virtual cars. From the body shell to the „wedding“ to final assembly, production chains are mapped completely virtually and realistically. Projects are created efficiently by integrating real CAD data and virtualisation in the real-time 3D environment SIMLINE.

- Pressing plants

- Car body welding cells

- Painting lines

- MAT basic assembly

- Battery production

- Pallet conveyor technology

- Automatic body bearings

- SKID conveyor technology

- Electric monorail system

- Thrust SKID lines

Customised solutions for your project

WinMOD not only provides you with real-time simulation software, we also support you as a reliable partner in introducing the system into your workflow.

Presentation

We will introduce you to our WinMOD system in a customised remote workshop in which the most important system features and workflows will be explained.

Training

We use sample projects to train you in the correct procedure and working methods in WinMOD. The training takes place online and can also be organised with reference to customer projects.

Project support

For the start of your first WinMOD project, we support you as part of our WinMOD project support.

Engineering

On request, we can prepare and test company-specific behaviour models, process components and WinMOD-SIMLINE components.

Since 1995, WinMOD® has stood for innovative virtual commissioning in all areas of technology worldwide. For its 30th anniversary, WinMOD® 8 presents itself as a completely new development - based on decades of project experience,...

The current SIMLINE development focussed on workflows in mechanical engineering and for production systems. In these areas of technology, the focus is on utilising existing CAD data,...

The WinMOD library Lib Libs now offers extended simulations for drive and air conditioning technology. Particular attention has been paid to the integration of Siemens SINAMICS frequency converters and the more precise...

Start your project with WinMOD

We will be happy to advise and support you with your first project. After a short online briefing, you can get started and test WinMOD straight away.

One call is enough!