Mechanical engineering

Development, production and maintenance of machines and systems

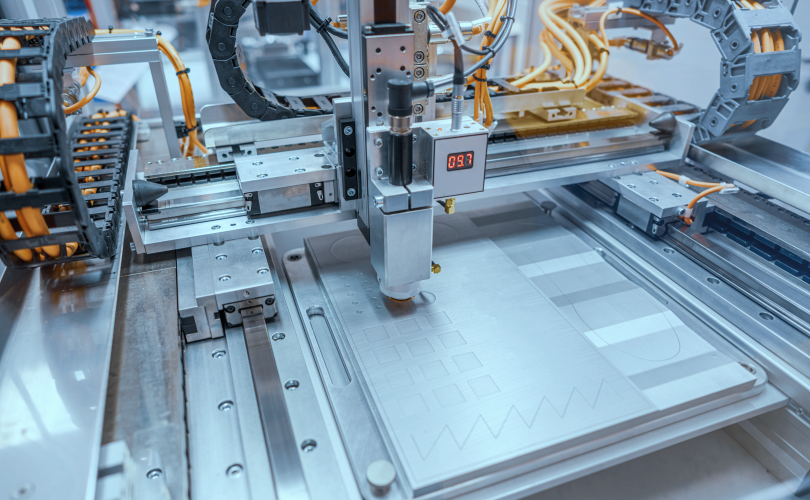

CAD-based real-time simulation

Mechanical engineering places very special demands on simulation systems for virtual commissioning (VIBN). Typical tasks in this area are requirements analyses, CAD-based real-time simulation (e.g. FEM/CFD), simulation of manufacturing and assembly processes with many different devices, coupling of different automation systems as well as testing and maintenance.

The 3D CAD data of the real machines and systems form the basis for the VIBN through direct import into the WinMOD-SIMLINE system. The components and piece goods are also integrated as 3D objects via CAD imports. In our 3D editor, you can place, combine and kinematise the machines and, if necessary, directly adjust axis pivot points, travel paths or gripper mechanics for the exact simulation of complex machines. The many different WinMOD-SIMLINE 3D sensors then record your component movements and machine axes with contour accuracy and analyse them in real time.

Variety in automation and devices

Im Maschinenbau kommt eine große Vielfalt an Steuerungs- und Bussystemen zum Einsatz. Eine Maschine für den europäischen Markt kann z.B. mit einer ganz anderen Steuerung ausgerüstet sein als für den amerikanischen. Genau hier liegt eine der Stärken des WinMOD-SIMLINE Systems. Es ermöglicht, viele dieser Automatisierungssysteme einfach und performant zu koppeln. Wobei besonders wichtig ist, dass Sie gleichzeitig mehrere und unterschiedliche Steuerungen an ein WinMOD System koppelt können, um so eine komplexe Anlage wirklich als Ganzes virtuell in Betrieb zu nehmen.

Auch die Antriebstechnik, sein es Servo-Achsen, Hydraulik, Pneumatik oder Frequenzumrichter, kann sehr vielfältig sein. Hier bieten wir im WinMOD Kundencenter umfangreiche Bibliotheken mit vielen virtuellen Geräten an. Diese beinhalten das reale steuerungsrelevante Verhalten mit Signalkopplung, Anlaufverhalten, Verfahrkurven, Betriebsmodi bis hin zu Kommunikationsprotokollen für z.B. Scanner. Sie als Anwender können diese direkt nutzen, gegebenenfalls einfach anpassen und auch selbst erstellen.

Further factory automation solutions

Sorting and picking systems for small goods such as cartons, plastic boxes or other piece goods. The goods are transported via classic roller conveyors, belt conveyors

as well as the typical cam roller tracks,

Belt curves and accumulating roller conveyors.

This technology area comprises conveyor systems that transport and sort pallets and pallet cages. The conveying elements are large roller and chain conveyors in combination with lifting, turning and sliding tables. Magazines for empty pallets are also typical here.

These systems are usually fully automated high-bay warehouses that are operated by storage and retrieval machines and controlled via distributed automation systems. The orders for storage and retrieval are generated via warehouse management systems.

Automated systems that pick up parts from A to B and set them down again with a defined orientation - typically for loading, sorting, picking or packing. Core systems are industrial robots (Delta, SCARA, 6 axes, Cartesian) or gantry axes.

Robotics plays a central role in modern manufacturing by enabling the automation of production processes and increasing efficiency and precision. Robots are used in various areas, such as welding, assembly, painting or packaging of products.

Production lines combine processes, material flow and control systems to create a production system with cycle and quality assurance. They consist of combinations of assembly, processing and testing stations. They also include transfer technology, buffers and often a highly specialised automation system.

Electric monorail systems are used as connecting conveyor technology over long distances. The overhead trolleys travel fully automatically with integrated electric drives and controls and are usually routed via a centralised control system.

This chain-driven overhead or floor conveyor technology is driven by continuously running power strands (chains). Transport trolleys are engaged, transported, disengaged at stoppers and buffered via chain dogs.

Automated self-driving vehicles as a connecting material flow solution. Driving takes place either completely track-free via defined lanes or markers (AGV) or via free navigation with automatic dynamic obstacle avoidance (AMR).

Engineering discipline for the development, manufacture and maintenance of machines, plants and production systems. Typical applications include machine tools, handling technology, automotive/aerospace, packaging and assembly systems.