Power & Free

Chain-driven overhead and floor conveyor technology

Power chain, driver mechanism and guide rails

Power & Free systems are chain-driven overhead or floor conveyors in which a continuously running drive train (power strand) transports free-running carrier trolleys via dogs.

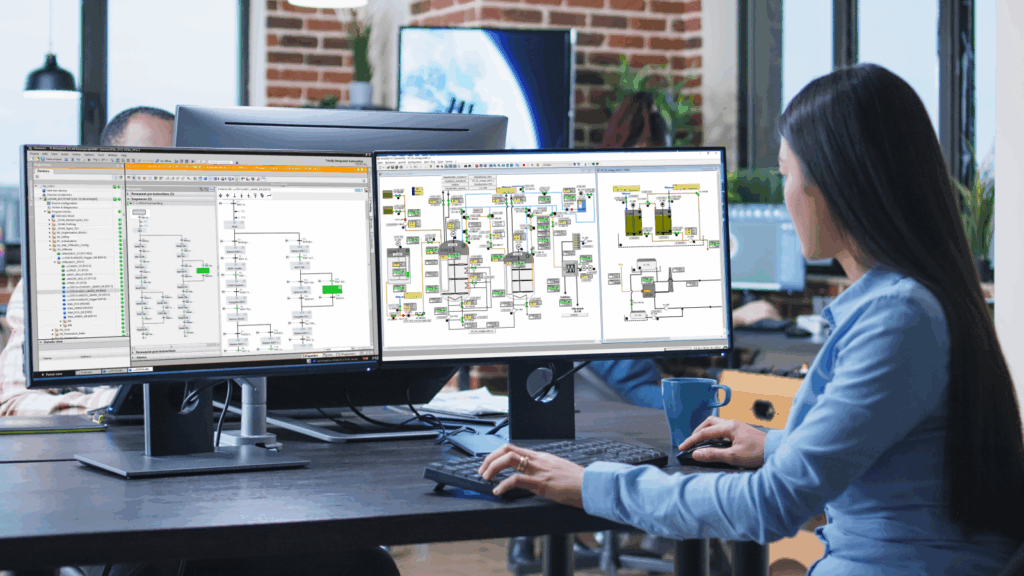

For this technology, WinMOD-SIMLINE offers a comprehensive 3D library with parameterisable power chains, rails and suitable components for lateral transport. Straight and curved track elements, switches, lifters, merges, drivers and stoppers are modelled realistically. This means that even complex processes such as the coordination of several vehicles, points control or congestion behaviour can be simulated in detail.

Transport trolleys and tracking

Carrier trolleys in Power & Free systems are - in contrast to the vehicles of electric monorail systems - without drive. The WinMOD-SIMLINE 3D trolleys reproduce this behaviour realistically: they are engaged by the continuously running drive train exclusively via mechanical dogs, moved and disengaged again at defined points. The carriages are stopped, buffered or moved independently of each other at stoppers.

Depending on requirements, the high-performance trolleys can also be equipped with lifting, rotating or swivelling units as well as switchable conveyed goods. Transport goods can be picked up and transported dynamically - supported by virtual sensors such as light barriers and scanners.

For communication purposes, the trolleys are usually equipped with RFID tags, barcode labels or other data carriers that enable clear identification and tracking.

Further factory automation solutions

Sorting and picking systems for small goods such as cartons, plastic boxes or other piece goods. The goods are transported via classic roller conveyors, belt conveyors

as well as the typical cam roller tracks,

Belt curves and accumulating roller conveyors.

This technology area comprises conveyor systems that transport and sort pallets and pallet cages. The conveying elements are large roller and chain conveyors in combination with lifting, turning and sliding tables. Magazines for empty pallets are also typical here.

These systems are usually fully automated high-bay warehouses that are operated by storage and retrieval machines and controlled via distributed automation systems. The orders for storage and retrieval are generated via warehouse management systems.

Automated systems that pick up parts from A to B and set them down again with a defined orientation - typically for loading, sorting, picking or packing. Core systems are industrial robots (Delta, SCARA, 6 axes, Cartesian) or gantry axes.

Robotics plays a central role in modern manufacturing by enabling the automation of production processes and increasing efficiency and precision. Robots are used in various areas, such as welding, assembly, painting or packaging of products.

Production lines combine processes, material flow and control systems to create a production system with cycle and quality assurance. They consist of combinations of assembly, processing and testing stations. They also include transfer technology, buffers and often a highly specialised automation system.

Electric monorail systems are used as connecting conveyor technology over long distances. The overhead trolleys travel fully automatically with integrated electric drives and controls and are usually routed via a centralised control system.

This chain-driven overhead or floor conveyor technology is driven by continuously running power strands (chains). Transport trolleys are engaged, transported, disengaged at stoppers and buffered via chain dogs.

Automated self-driving vehicles as a connecting material flow solution. Driving takes place either completely track-free via defined lanes or markers (AGV) or via free navigation with automatic dynamic obstacle avoidance (AMR).

Engineering discipline for the development, manufacture and maintenance of machines, plants and production systems. Typical applications include machine tools, handling technology, automotive/aerospace, packaging and assembly systems.